PRODUCT DESCRIPTION

Floor deck panel specifications

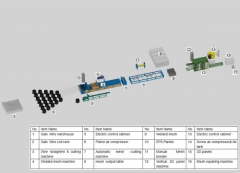

Composition of Floor deck roll forming machine

Manual de-coiler

Roll forming main machine

PLC control system

Hydraulic station

Cutting system

Manual out table

Hydraulic pressing system

Main parameters for the machine

|

Material of shaft |

45# steel ,by heat treatment |

|

Shaft diameter |

90mm |

|

Main machine frame |

400 H steel |

|

Shear Mould |

Gr12 |

|

Number of forming rollers |

24 rows |

|

Transportation system |

Chain transportation |

|

Thickness of chain |

0.6inch |

|

Main motor power |

18kw |

|

Pump station power |

7.5kw |

|

Forming speed |

8-10m/min |

|

Rolling thickness |

0.8-1.5mm |

|

Computer system |

PLC control |

|

Overall dimension |

14m x 1.5m x 1.3m |

|

Weight |

13000kg |

Special size can be made according to customer’s requirement.

Our roll forming machine has which advantage?

Reference:

C-section roll forming machine, please refer http://www.hbhscn.com/c-section-steel-roll-forming-machine_p34.html

Glazed tile roll forming machine, please refer http://www.hbhscn.com/glaze-roof-tile-steel-roll-forming-machine_p37.html

Wall or roof panel roll forming machine, please refer http://www.hbhscn.com/wall-roof-panel-steel-roll-forming-machine_p40.html

Down pipe roll fomring machine, please refer http://www.hbhscn.com/down-pipe-roll-forming-machine_p42.html

EPS/color steel sandwich panel machine, please refer http://www.hbhscn.com/eps-color-steel-sandwich-panel-machine_p30.html